Announcements

Announcements

The CMR University Makerspace is a dynamic innovation hub designed to support hands-on learning, creativity and interdisciplinary collaboration. Located at the Bagalur campus in Bengaluru, the space facilitates the prototyping phase of the Design Thinking process by providing access to industry-grade tools and technologies that allow students, researchers, and entrepreneurs to build and test real-world solutions. By democratising access to tools such as 3D printers and laser cutters, the Makerspace empowers them to develop practical skills through hands-on creation. Its fully functional prototyping lab that houses advanced machines and quality materials that support student and innovator projects. Designed to promote a culture of hands-on learning, the Makerspace enables individuals to explore new ideas, create working prototypes, and bring concepts to life.

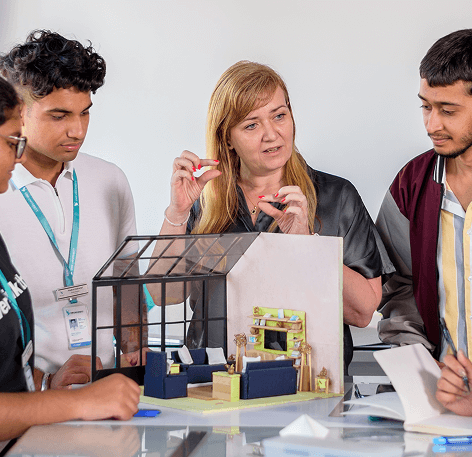

The Design Thinking curriculum at CMR University complements this hands-on environment by guiding students through the five stages — Empathise, Define, Ideate, Prototype, and Test. Students begin with field-based research to understand real-world challenges, define key problems, develop ideas, and then use the Makerspace to build and test prototypes. Learning is further strengthened through short-term optional Design Thinking–style courses conducted at the Makerspace, which focus on skills such as 3D printing, testing methods, and operating specialised tools and machines, ensuring students gain practical, real-world prototyping experience beyond the classroom.

Rooted in the university’s learning-by-doing philosophy, the Makerspace encourages experimentation, iteration, and problem-solving through a user-centred approach. It offers a platform to test and refine products, validate solutions, and develop scalable models that are both impactful and future-ready. Students from diverse disciplines come together here to learn, build, and lead through innovation.

The Makerspace methodology at CMR University is a hands-on process of discovery, where students explore technology through microcontrollers, sensors, signal processors, and creative software to build responsive systems. Learning is driven by playful experimentation through app-based coding, gaming, and system hacking. Design challenges follow a structured yet flexible journey, from problem identification and user research to insight synthesis and prototyping. Each idea is tested, refined, and reimagined, building critical thinking, collaboration, and the creative courage to work confidently through ambiguity.

The Makerspace offers short-term, optional certification courses that provide hands-on exposure to tools such as 3D printers, laser cutters, CNC routers, and testing equipment. Rooted in Design Thinking, these courses emphasise real-world prototyping, iteration, and user-centred problem-solving. Students move beyond theory to build functional models and validate ideas through experimentation. The outcome is strong technical proficiency, creative confidence, and industry-relevant skills.

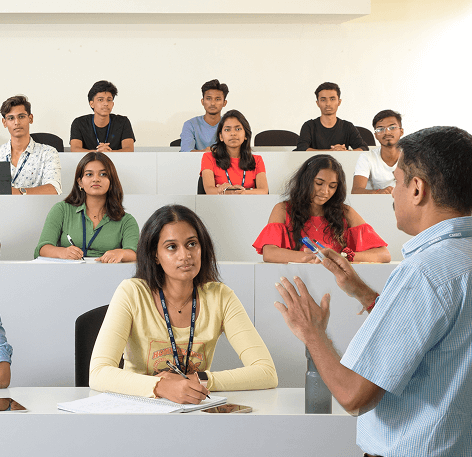

Regular innovation showcases, workshops, and expert talks connect students with industry practitioners, researchers, and design leaders. These platforms expose learners to emerging technologies, real-world applications, and evolving industry standards. Students gain insights through live demonstrations, discussions, and project exhibitions. Together, these experiences broaden perspective, inspire innovation, and strengthen professional readiness.

Whether it’s coding, gaming, or hacking, makers explore through play — discovering, testing, and creating as they learn.

Understand the full context of a situation and recognize its problem areas. Map what you know to define user needs, clarify priorities, and focus attention where it matters most.

Set aside assumptions and connect genuinely with users and stakeholders. By understanding their values, experiences, and mindsets, you can design solutions that are truly meaningful and human-centered.

Investigate the challenge to gather insights and test assumptions. Analyse data and observations to validate or refine ideas and develop a deeper understanding of the context.

Understand the full context of a situation and recognize its problem areas. Map what you know to define user needs, clarify priorities, and focus attention where it matters most.

Generate a wide range of ideas through creative brainstorming and divergent thinking. Encourage curiosity, experimentation, and “what if” thinking to uncover innovative possibilities.

Refine promising ideas into actionable concepts. Create prototypes to visualize and test your ideas early—learning, improving, and reducing risks through iteration.

Share prototypes with users and stakeholders to gather insights. Use feedback to refine, adapt, and strengthen your design for greater impact and usability.

Communicate your solution clearly and compellingly. Share your process, showcase your learnings, and inspire others to build, collaborate, and innovate further.

Evaluate what worked, what didn’t, and what could be improved. Reflection fosters growth, deepens understanding, and strengthens your next design journey through blended learning.

Design Thinking is a human-centered, creative approach to solving complex problems across diverse fields — from engineering and healthcare to climate adaptation.

As a process-driven and iterative method, Design Thinking encourages exploration, experimentation, and continuous learning. This approach builds resilience, adaptability, and an innovative mindset that drives meaningful progress.

It emphasizes early prototyping and testing, helping innovators learn from failures, and uncover valuable insights. This helps connect ideas in unexpected ways.

At CMR, our vision is to ‘Nurture creative thinkers who will drive positive global change.’ It empowers students to become critical, collaborative, and empathetic problem-solvers capable of applying cross-disciplinary thinking.

The Makerspace at CMR University features a comprehensive range of industry-grade equipment that supports prototyping across disciplines—from engineering and design to architecture and media. Students and registered external users have access to these tools within the lab, and many of them are also available for short-term commercial rental. The CMRU Makerspace offers access to a wide range of tools and machines, suitable for everything from simple models to advanced engineering prototypes. These are available for in-lab use by CMR students and registered users, and also for external commercial rental upon request.

External users, startups, and creators can rent selected tools and machines on an hourly or project basis. Rental services include machine usage along with necessary safety gear, basic consumables, and technician assistance where required. Terms of usage and pricing are available on request through the Makerspace coordination desk.

All equipment is maintained regularly and calibrated for precision. Training is provided before first-time use to ensure safe and efficient handling.

The CMRU Makerspace regularly hosts national and international innovation challenges, design sprints, and themed competitions. These events offer students exposure to emerging technologies, collaborative techniques, and global maker movements. Participants have the opportunity to work on real-world briefs, build connections, and gain recognition for their creativity and technical skill.

Innovations developed in the lab are frequently showcased at university symposiums, exhibitions, and public platforms. Students are encouraged to present their work, receive feedback, and iterate for improvement. Many of these projects go on to become part of social initiatives, academic research, or entrepreneurial ventures.

The Makerspace is a launchpad for student-led innovation. It hosts internal and external competitions, innovation challenges, design sprints, and global maker events. Students gain exposure to international techniques, collaborative problem-solving, and real-world briefs from industry and social sectors.

These platforms not only validate student projects but also open doors to research, internships, and entrepreneurship. Winning ideas are showcased at university symposiums, exhibitions, and on CMR’s digital platforms—creating a strong portfolio for the future.

Whether you’re a student looking to build your first prototype or an innovator seeking access to world-class tools, a faculty member guiding research, or an entrepreneur seeking access to world-class tools, CMR University’s Makerspace is the space for you.

To schedule a visit, book a tool, or partner on a project, reach out to our coordination team at makerspace@cmr.edu.in

Let’s build something extraordinary!